| |

| Abstract

Virtual product development today has become a

complex process involving CAD, FEA, CAE, and physical testing. Material

properties form the glue that link the simulation and real life

behavior together. Most often, the properties of the materials used

in different stages of the product life cycle vary depending on

the application. Hence, the engineers and technicians within the

enterprise need to have access to not just the simple single point

properties that help determine the suitability of a material, but

also the more detailed behavioral property data that affect design,

simulation and failure analyses. A common platform for the storage

and effective deployment of these properties system wide is critical

to the efficiency, cost, and quality control through PLM. We present

a technology, Matereality that accommodates diverse properties of

all the different materials used by an enterprise, its suppliers

and collaborators. The cost benefits are immediate, besides improved

interoperability and consistency in material data use through the

enterprise.

Introduction

As the role of digital product development continues

to solidify within enterprises [1], the need for systems to support

the needs for this new technology become more and more urgent. In

the past, CAE was relegated to a corner of the product development

process where timeliness and accuracy were secondary to the core

purpose of verifying the viability of the technology itself. With

the mainstreaming of the technology, these luxuries are no longer

available to CAE analysts and it is now imperative to deliver timely

and accurate information to facilitate the design process.

In such an environment, there is no place for

unproductive work nor is there tolerance for error in analysis because

now, key design decisions are being based upon the results of a

CAE simulation. Indeed, the viability of CAE groups and the industry

itself would be called into question should it be found to be lacking

in its ability to provide sustained value to the enterprise. This

is a novel burden for the CAE industry and to resolve it, one must

look for parallels in other industry horizontals to see how they

have adapted themselves to the challenge [2]. We believe that supply

chain integration and standards based data management are key technologies

that will help to streamline and increase productivity in the digital

product development industry.

That being said, it is clear that significant

challenges exist in the achievement of these goals. Unlike the financials

business or even the manufacturing horizontals, product development

involves a huge variety of applications. CAE itself could involve

NVH, stiffness/failure, crash/rate dependency, thermal/thermomechanical,

forming/process simulation, large deformation-hyperelastic/hyperfoam,

stress relaxation/creep-viscoelasticity. Case-specific complexity

is introduced in each vertical in which the development occurs.

Further, materials play a key role in fleshing out this complexity

as each vertical leans toward its own favorite materials, which

it deems appropriate for the manufacture of its products. In this

paper, we tackle the materials problem and demonstrate a framework

that uses both supply chain integration and standards based data

management technologies to provide comprehensive content management

for enterprises. We illustrate the benefits of this technology to

the enterprise and provide a model upon which companies can save

time and money while reducing risk in the product development process.

Current situation:

the case of the 'Lone Ranger' CAE analyst.

CAE analysts today perform a variety of simulations on products

that are constituted from many kinds of materials. Each simulation

requires the use of specific material models that describe the material

behavior in that particular application. It is critical that they

use for these material models, quality properties that are self-consistent

and application appropriate. The material models are usually created

by the analyst after expending anywhere between several hours to

a week of time and effort to convert the material properties available

to them into the format required by the CAE analysis. Consequently,

material models are highly cherished and each analyst has her/his

own private model collection. Because of the sophisticated needs

of material properties for designers, there are no comprehensive

data stores that can store such data in a truly digital format.

Accordingly, this valuable data sits on the analyst's desktop or

within a small group and is typically not available to the enterprise.

Analysts typically will not share models for fear of use in inappropriate

applications. Because models do not contain the underlying material

properties and data pedigree, their value is further diminished;

the data is not easily re-used since other users cannot judge its

quality/authenticity. The enterprise has fragmented access to this

data and a system for streamlined sharing with collaborators is

difficult. A NIST study [2] estimates that the automotive industry

alone loses $1B per year due to interoperability problems related

to data that is no longer available. Foundyller further supports

this claim by noting that such information is usually never available

at the time when critical decisions are being made[3]. This unavailability

of data costs in terms of direct dollars for re-testing, and time

loss, besides adding to the risk of misused data in the design process.

Such private, disintegrated data stores within the enterprise represent

what we call the Lone Ranger scenario.

|

|

|

Desired

situation: the need of the global enterprise

As the enterprise transforms the way in which it designs and manufactures

products, moving from monolithic to distributed models, the IT infrastructure

must be similarly aligned to accommodate the requirements of the enterprise.

Just as materials are sourced from suppliers to the enterprise, so

must content management systems be able to seamlessly source data

and digital information that may be used to represent the materials

in the digital world.

Because a material is a clearly defined entity,

all the information related to it must also be self-consistent and

accurately represent the material in the digital world. Further,

all analysts in the present and the future, globally must have access

to the same information so that analysts anywhere and at any time

produce the same consistent digital work product. This is a daunting

task without a framework capable of handling such complexity. Matereality

represents such a sophisticated solution, which by providing an

integrated interoperability platform to deploy any kind of material

data, is then used for selective shared access by users within and

outside the enterprise.

Last but not least, since so much now hinges on

the accuracy of a digital simulation, it is clear that the material

properties being used must be verifiably accurate, traceable to

source and applicable to the task at hand. Conventional public material

databases list a variety of properties for selection purposes but

are just not suited for the product design application. In the new

paradigm, it is unconscionable for an analyst to simply pick a material

property out of a handbook or generic database with no idea about

how good the data is or whether it actually represents his or her

material in the actual product application. A clear case is therefore

made for the enterprise to invest in the development, storage and

deployment of material properties that are pertinent to the task

at hand. At first instance, this might seem like an impossibly expensive

task; however it must be remembered that a lot of the desired data

exists. It is simply not accessible to the analyst. Companies each

year, spend millions of dollars on testing. This data is owned and

stored by the entities that generate it. For example, a material

supplier may generate visco-elastic or high strain rate data for

use in a particular project. Because of the sensitivity of such

information, the data will never appear in a public database. Nonetheless,

this data is of significant value to client enterprises that seek

to use this material in their products. In a supply chain type IT

infrastructure, the client enterprises should be able to identify

and then request access to such types of information. The supplier

should be able to provide or deny access to its data depending on

the nature of its relationship with its client.

Pertinence:

making sure it is application appropriate

Using the right data for a particular application is of vital importance

to virtual product development. This is because, contrary to common

perceptions, the properties of materials are not necessarily unique.

Properties may vary for a number of reasons ranging from materials

variations to the parameters used in the test. Some of these variations

in a measured property are easily understood by the analyst: variation

of stress-strain behavior with temperature or strain rate; viscosity

with temperature or shear rate, or hyperelastic properties to name

but a few.

Other variations are more the purview of

the testing laboratory but need to be understood nonetheless. These

include variability of the measured properties themselves, information

about the samples and test methods used for the testing, uncertainty

of the measurements. For example, it is practically impossible to

describe fatigue behavior for practical use without an understanding

of the type of test samples used, the method and mode of deformation

and the criteria used by the laboratory to describe failure. Even

in the case of stress-strain behavior, the definition of yield can

be misinterpreted between the test laboratory and the data consumer.

As enterprises strive toward greater precision, it is therefore

impossible for the engineer to neglect to use such valuable information,

which is now readily available within the framework of a material

data management system.

|

|

Figure 1 Contrasting Lone Ranger scenarios with

domain-type selective sharing. |

Even

more factors exist in ensuring that material data is application appropriate.

An engineer may have cause to question the quality of the data source

depending on whether they are accredited, or whether or not they publish

the variability of the test results. Being able to examine all this

information prior to using a piece of material data is a vital part

of the design process providing a new level of comfort and peace of

mind to a busy analyst.

Fidelity: getting it right each time

Because of the Lone Ranger scenario described earlier, there is a

significant risk that CAE analysts in a distributed enterprise are

performing related or duplicate simulations with material models that

are not compatible. This can happen even within small groups because

of the lack of communication within teams. Such a scenario causes

unnecessary risk adding to design uncertainty. Some organizations

use product data management (PDM) systems in an attempt to resolve

this problem. PDM systems permit the analyst to attach a material

model input deck to a simulation. This is only a partial solution,

however; there is no way to ensure that teams are working off the

same page with respect to material data. Sharing input decks within

a CAE team ensures fidelity when different analysts are seeking to

describe identical material behavior. Often, however, teams need to

perform variations on a particular simulation. Input decks do not

contain the information needed for the analyst to make a decision

about the appropriateness of the model to his simulation. They fail

to store critical decision making information that would permit the

analyst to make an informed choice.

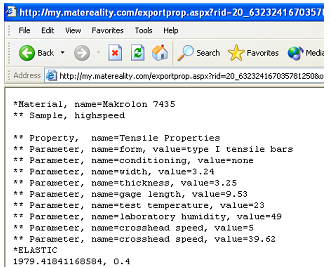

The use of a material data management system

represents a paradigm shift in this scenario. Here, the material property

data for the enterprise is staged at a single web-based location.

All the underlying property data and supporting information related

to the material model parameters is stored. The analyst can, should

they desire, perform sanity and appropriateness checks to ensure that

the data is right for them. Rather thanstore

input decks as incomprehensible data files, the system simply exports

the data into the desired export formats upon demand. Analysts system-wide

would then be able to access identical information for their applications,

ensuring fidelity.

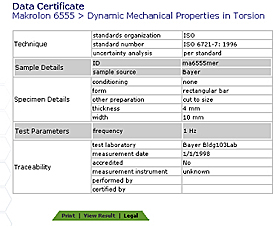

|

|

Figure 2 Data certificates allow the assessment

of data pertinence. |

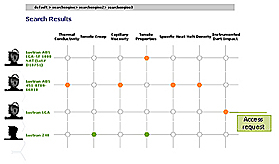

The supply

chain: obtaining content from others

Most enterprises today dynamically manage a wide range of materials

they use in their products. Very few companies today manufacture products

using a small static list of materials. As products evolve and materials

change, data pipelines must exist to ensure a smooth flow of fresh,

pertinent content[4]. This is vital to the material data management

system and to its longevity in the enterprise. The material data needed

by the enterprise logically comes from two types of sources. Internal

laboratories generate data for a number of reasons; such data must

be stored within the system to be disseminated as needed. Very importantly,

however, in a collaborative environment, material data comes from

sources external to the enterprise. It is critical that members of

an enterprise be able to probe the content of its collaborators to

locate data that might be useful to their activity. A system of access

requests ensures that the owners of information maintain control over

the use of their data. The attractiveness of this scenario stems from

two important benefits: ready availability of high quality, pertinent

material properties; time and money savings from not having to test.

In fact, it must be noted that these benefits apply even in cases

where the properties exist within the enterprise. All too often, analysts

may simply not know that data they need exists within the enterprise,

nor may they know whom to ask for the information they need.

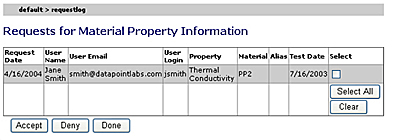

|

|

Figure 3 Input decks are generated on-the-fly

once user approves the data. |

Figure

4 Using access requests to control data flow.

Control of

content flow: privacy and fiefdoms

Enterprises are complex entities with widely varying needs with respect

to the use of information. Certain types of data are purposed for

a particular application. For example, data provided for purchase

decisions must simply not be used for other purposes, such as design.

In the case of a plastic fuel tank design, 'purchasing' material data

will evolve around properties of the virgin plastic while the CAE

analyst must necessarily use properties generated after fuel soaking.

In another example, sensitive material data may be generated for the

R&D team which must be protected from access by unauthorized users.

It is clear that a flat database would not be able to handle such

a scenario and would therefore be of limited use to the enterprise.

It would be relegated to storing only the information that anyone

can see, the lowest common denominator. This is a self-defeating and

non-productive scenario which guarantees the eventual demise of the

system. A good material data management system permits the selective

dissemination of material data within the enterprise, respecting the

need for privacy. It would permit highly sensitive information to

be completely hidden, accessible only to those authorized to use it.

Other less sensitive information could be found by users of the system

but not accessible without permission of the data controllers. The

lowest common denominator of public data would be published for all

to see. |

|

|

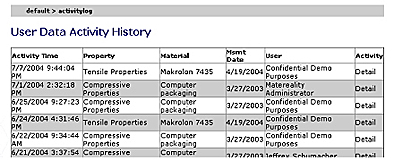

Risk

mitigation: access control and record keeping

Because a single system must be used for optimal

management of public and private data of the enterprise, access control

becomes an important aspect of a material data management system.

It permits the enterprise to control the dissemination of information

to authorized personnel with a level of flexibility analogous to current

business practice. This includes but is not limited to the following

scenarios: a single user having access to one or more material property

datasets; a designated group of users having access to a data collection

that is pertinent to their activity in the business.

Figure 6 Access logs track data usage.

To ensure proper utilization of the system,

access logs provide detailed records of data access, activity and

use.

Conclusion

Design process enhancement is a major topic

today in cost reduction and system improvement in the enterprise.

Material property data constitutes a small but significant aspect

of the knowledge base of the enterprise. In the context of the CAE

analyst and the design engineer, it is the information that binds

their work to reality. Weakness in this area raises the level of risk

to the enterprise and lowers the efficiency of the design process.

A material data management system creates a robust infrastructure

within the enterprise that permits storage and controlled dissemination

of high quality material properties. It is extensible to the collaborative

environment allowing efficient information interchange and cost and

time savings by preventing attrition of material data.

References

|

|

Figure 5 A single system to store both public

and restricted data. |

- 1. C. Lemyze, ' Transforming into Best-in-Class

Manufacturers through PLM', Desktop Engineering, (2003) http://www.deskeng.com/articles/03/sept/commentary/main_dig.htm

- 2. J. E. Fowler, "Manufacturing

Software Interoperability: Problems, Cost, Mitigation" Daratech

Summit, (2000) http://www.mel.nist.gov/msid/sima/daratech/sld001.htm

- 3. C. Foundyller, "Opening Statements",

Daratech IDPS Conference (2004)

- 4. "Needed: Suppliers who can collaborate

throughout the supply chain" Supply Chain Management Review,

(http://www.manufacturing.net/scm/index.asp?layout=siteInfoWebzine&view=Detail&doc_id=96527)

|

|

|

|